Apr 2021

Making a mask during a pandemic

Till early 2020, the facemask was an uncommon sight. Nobody would have imagined that a mask would become such an integral part of our lives - and faces. Then came the pandemic.

A few weeks into the lockdown, customers began to ask for a mask that was safe and comfortable. We had to do something. But we faced a few fundamental challenges.

Fabric & filters

Tees are made from fabric that is knit. Knit fabric is loosely structured. What masks need is tightly structured fabric, which could be woven or non-woven. Many companies made - and still make - masks from knit fabric, but that was a no-go area for us.

Our supply chain had no experience with woven and non-woven fabric. We learned from scratch. And finally narrowed it down to three layers.

Design

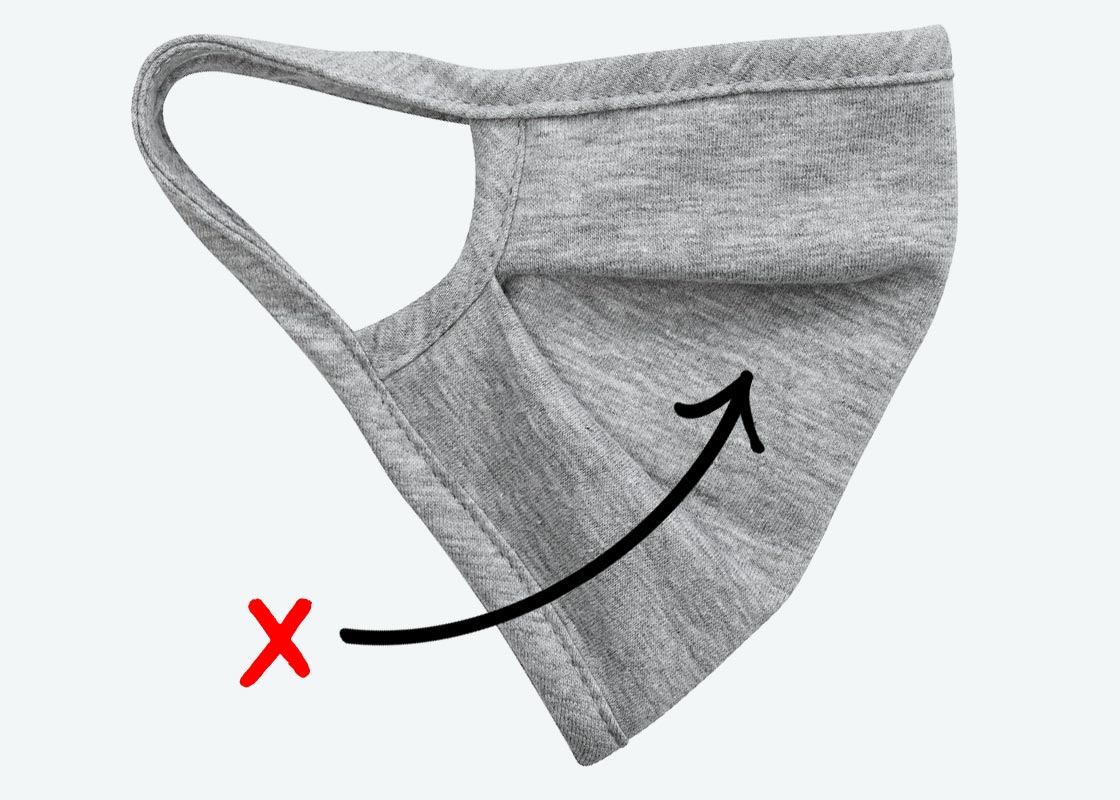

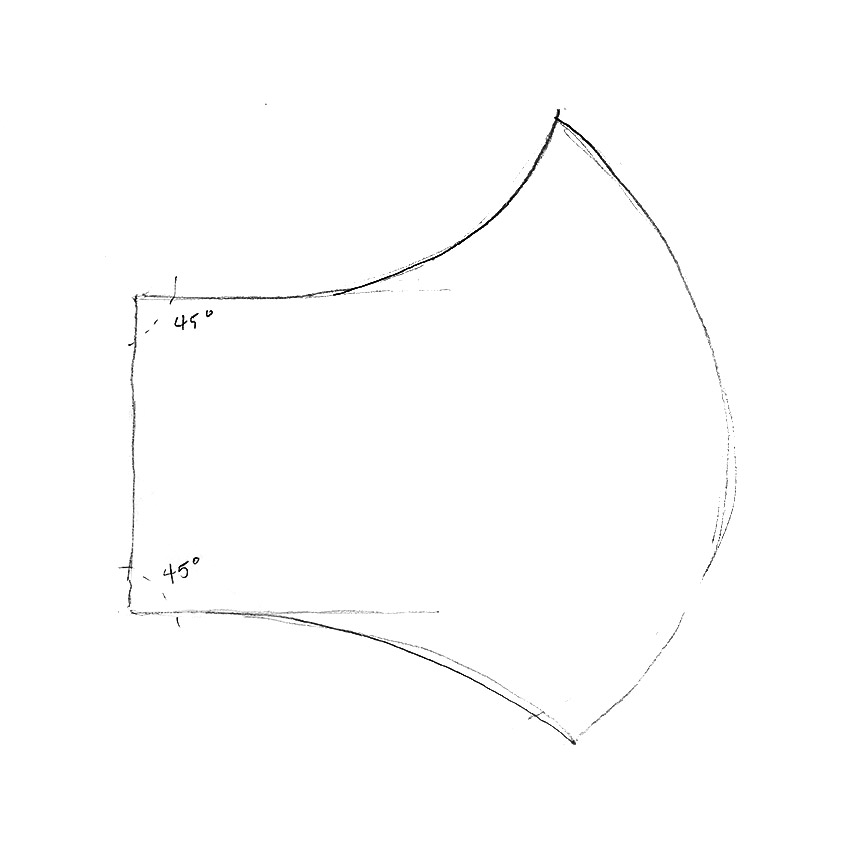

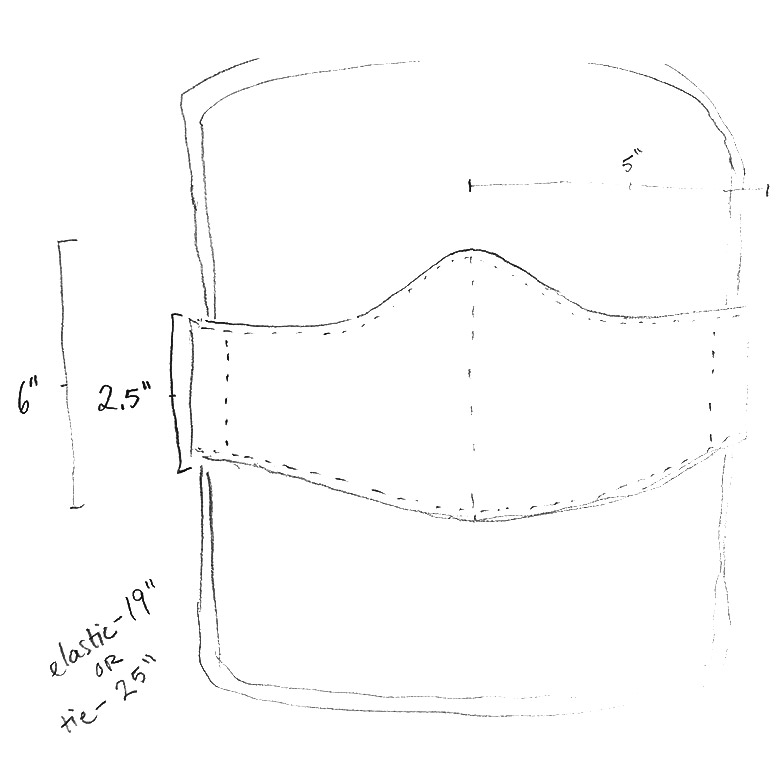

We take months to design. Time, we didn't have. Our pal Bennett from San Francisco was already sewing masks for herself and friends. She had an incredibly thoughtful design. It covered the face fully, and because the elastic went round the head instead of the ears, it could be worn for hours comfortably.

We licensed her design, put it to test, adapted it to our custom N95 filter-based fabric and got to work. Thank you Bennett!

Packaging

We had to make sure the masks were produced in good hygiene and sealed at source to keep out moisture. Our inspiration came from Sambhar delivered during the lockdown. It arrived in sealed aluminum foil, fresh and with no leaks whatsoever.

But this wrapper was too thin and wrinkled easily. We went through options. Found a significantly heavier one. Put together a design that felt reliable and solid.

And got a machine to seal these immediately on the production floor.

Economies of scale

Here’s what the bill of material looked like –

| 1K Units | 10K+ Units | |

|---|---|---|

| Fabric | 35.00 | 19.50 |

| Filter | 6.00 | 0.80 |

| Elastic | 14.00 | 2.50 |

| Sewing | 65.00 | 46.00 |

| Packaging | 30.00 | 12.00 |

| Freight | 8.00 | 8.00 |

There was no way the mask would be affordable unless we got into economies of scale. Going from producing a thousand units to tens of thousands at one-fifth of your average selling price is no easy task. Neither is negotiating and re-negotiating during a pandemic. But there was no other way.

Reception

The masks were launched for pre-order in June 2020 and shipped 4 weeks later. Reviews were mixed. But one comment was consistent - the mask was too tight.

Got my shipment of #Mask by @MarchTee today. First impressions is that its uncomfortably tight (puts a lot of pressure on the nose). Let's see if I get used to it, or if the stress reduces after a few uses. pic.twitter.com/8vX9TGzvhR

— Pallab De (@indyan) September 12, 2020

We got back to work, made a larger regular size and designed a new plus-sized mask – something no other players were doing. Six weeks later, the second round of masks went out.

Yes. Masks are Great. I've been using them since the Mask v1. I've Specs with Long hair(bun) and they fit great. Just decide whether you want a Regular or Large size.

— Rutvik Jain (@BeingRutvik) March 22, 2021

Making the mask was the hardest thing we've done after the first March Tee. There were dozens of firsts, crazy restrictions during the lockdown, a ticking clock and the responsibility of the user’s safety in our hands. But there was a genuine need and we wanted to pitch in.

To our customers, thank you for your support. We send to you, your families and friends much love and the strength to come out of this stronger.

Stay safe,

Team March